World Class Flexo Printing Sleeve Solutions

Tech Sleeves designs and manufactures the highest quality hard sleeves in market. We use the best materials and processes to ensure that our sleeves are durable and can withstand any printing press environment.

Designed for High Speed Presses

Extreme Durability and Strength

Chemical Resistant

Sleeve Features & Options

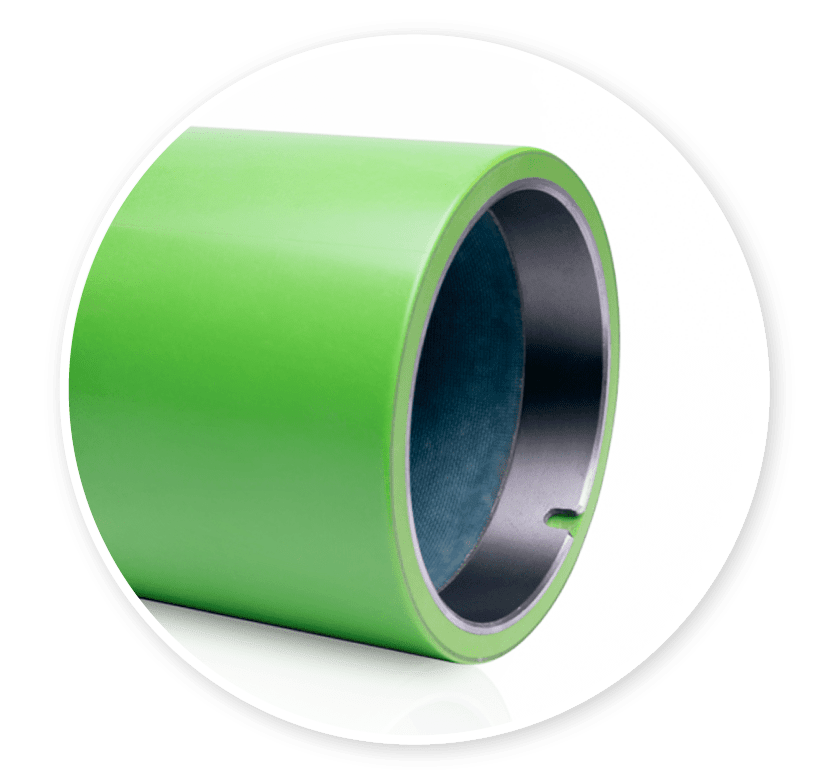

Inner Metal Ring

Most strong and durable slot solution. The diameter of the metal ring is slightly wider than the core, to ensure easy mounting and prevent the damage of the mandrel.

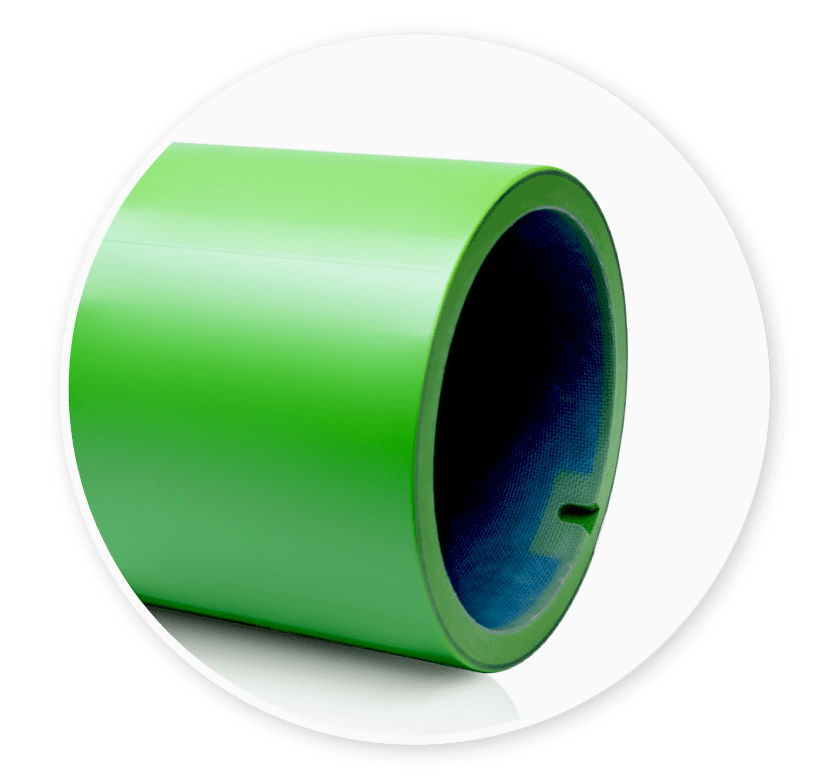

Hard Sealed Edges

Protects the core from damage by ink and solvents. Ensures the longevity of the sleeve.

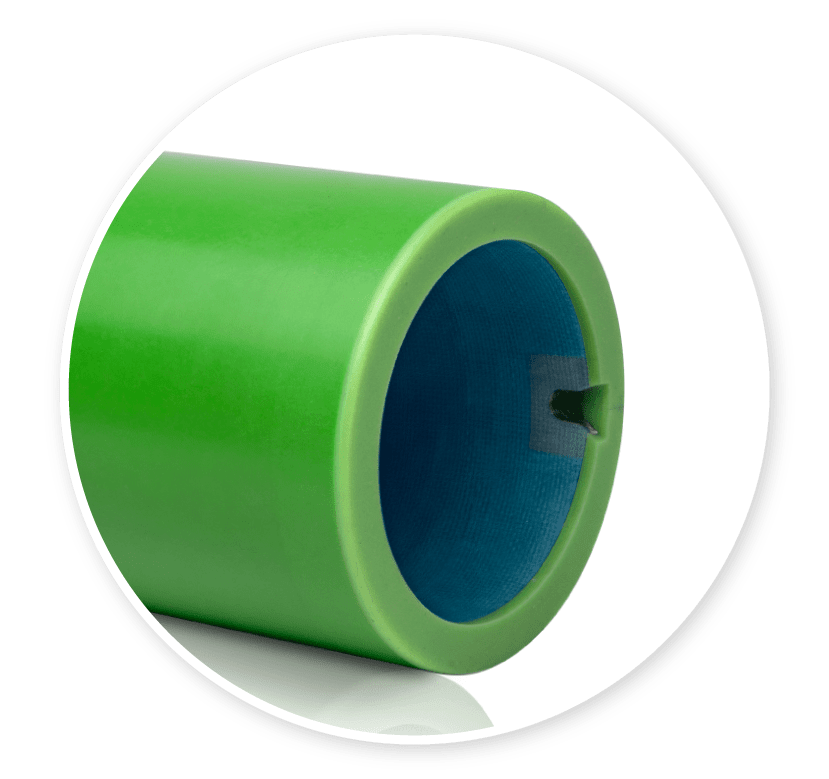

Rubber Sealed Edges

Decreases wear and tear of the sleeve while increases durability. The edges are shock absorbent, therefore the chances of impact damage on the side of the sleeve are reduced.

Smart Sleeve

Equipped with RFID chip and magnet to store identification numbers and repeat sizes to simplify the identification process.

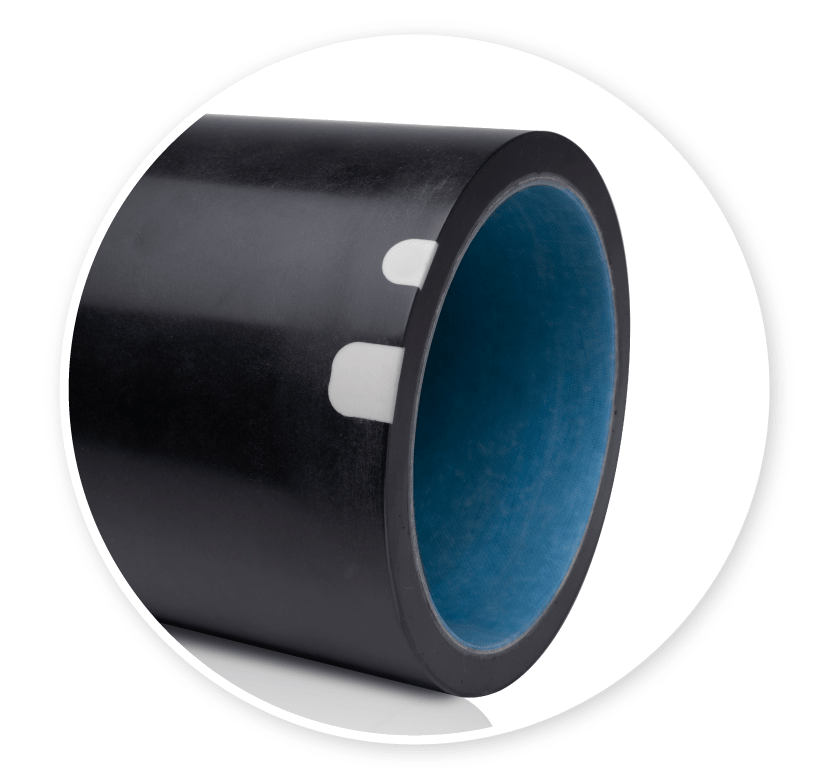

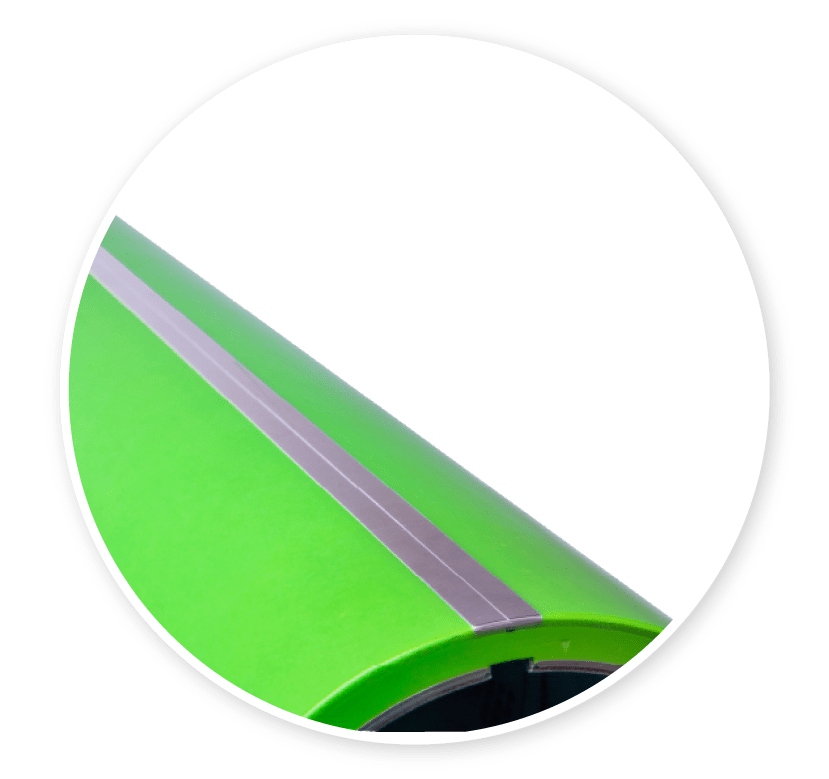

Metal Cutting Line

Helps the operator with cutting and prevents sleeve damage. The cutting line has an optimum width of 6mm, which improves the balance of the sleeves.

Sleeve Layers Specifications

- 1 mm- Flexible and expandable innermost core.

- Contains Dyneema® that offers maximum strength with minimum weight.

- Dyneema® doesn’t fray and is up to 40% stronger than aramid fibers such as Kevlar®.

- Prevents slipping of the sleeve on the mandrel.

- Extremely durable and resistant to moisture, UV light and chemicals.

- 1 mm – Compressible pre-compressed Foam Layer.

- The compressible pre-compressed Foam Layer has high rebound resilience and is up to 50% compressible without bulging.

- Resistant to permanent deformation, good abrasion resistance, resistance to aging, weathering and cleaning solvents used for polymer plate cleaning.

- Stitch, Bonded and Compressed Tech Core Material in various thicknesses.

- Contains a filament fiber base which is volumized by fiber glass infused with Epoxy Vinyl-Ester-Resin.

- Light weight with extreme high flexural strength and form stability.

- 2,5 mm – Outer surface layer contains Epoxy Vinyl-Ester-Resin reinforced with technical filaments and polyester fleece.

- The optimized thickness of the outer surface increases stiffness and forms stability over time

- High chemical and temperature resistance with excellent tape mount and demount properties.